What is end forming?

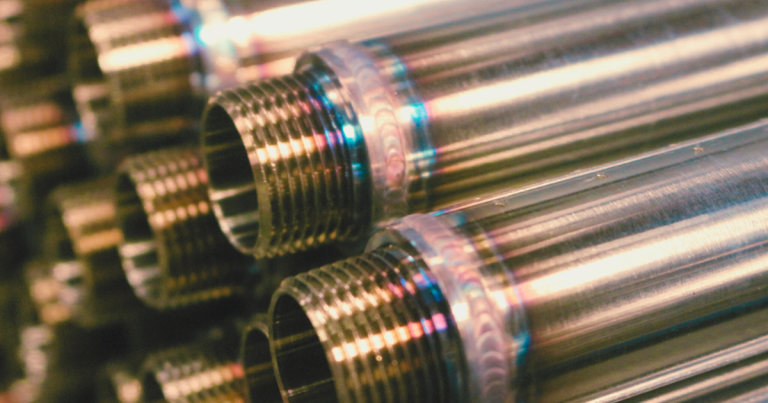

End forming is a specialised tube fabrication process that reshapes the end of a tube to create features such as flares, beads, expansions and reductions. It turns standard tubes into precision components that mate cleanly with other parts, improve sealing and increase strength across sectors including automotive, aerospace, HVAC and industrial manufacturing.

Rather than leaving a simple square cut, the end-forming process adds engineered features that solve connection challenges, reduce leaks and optimise overall system performance. Understanding the options within end forming helps manufacturers choose reliable, cost-effective tube fabrication and pipe-bending solutions.

Understanding End Forming: The Fundamentals

Furthermore, end forming involves the controlled deformation of tube ends using specialised machinery and precision tooling. The tube end forming process works by applying mechanical force to reshape the tube material without cutting or removing material, making it both cost-effective and waste-free.

Moreover, the technique can create both simple and complex geometries, depending on the application requirements. Whether you need a basic flare for a hydraulic connection or a complex multi-step profile for aerospace applications, the end forming process delivers precise, repeatable results that meet demanding specifications.

Key Characteristics of End Forming:

- Material Conservation: No material is removed, only reshaped

- Precision Control: Tight tolerances achievable through advanced tooling

- Versatility: Works with various materials including stainless steel, aluminium, brass, and carbon steel

- Integration: Often combined with tube bending and other fabrication processes

Common End Forming Types and Applications

Flaring

Consequently, flaring expands the tube’s end diameter to create connection points for fittings or sealing surfaces. This end forming technique is essential in hydraulic systems, fuel lines, and brake systems where leak-tight connections are critical. The expanded end provides increased contact area for improved sealing performance.

Common Applications: Automotive brake lines, hydraulic systems, plumbing connections

Beading

In addition, beading creates raised circumferential ridges that provide mechanical retention for hoses, clamps, or other components. These features prevent slippage under pressure or vibration, making them vital in automotive and heavy equipment applications.

Common Applications: Exhaust manifolds, turbocharger connections, HVAC systems

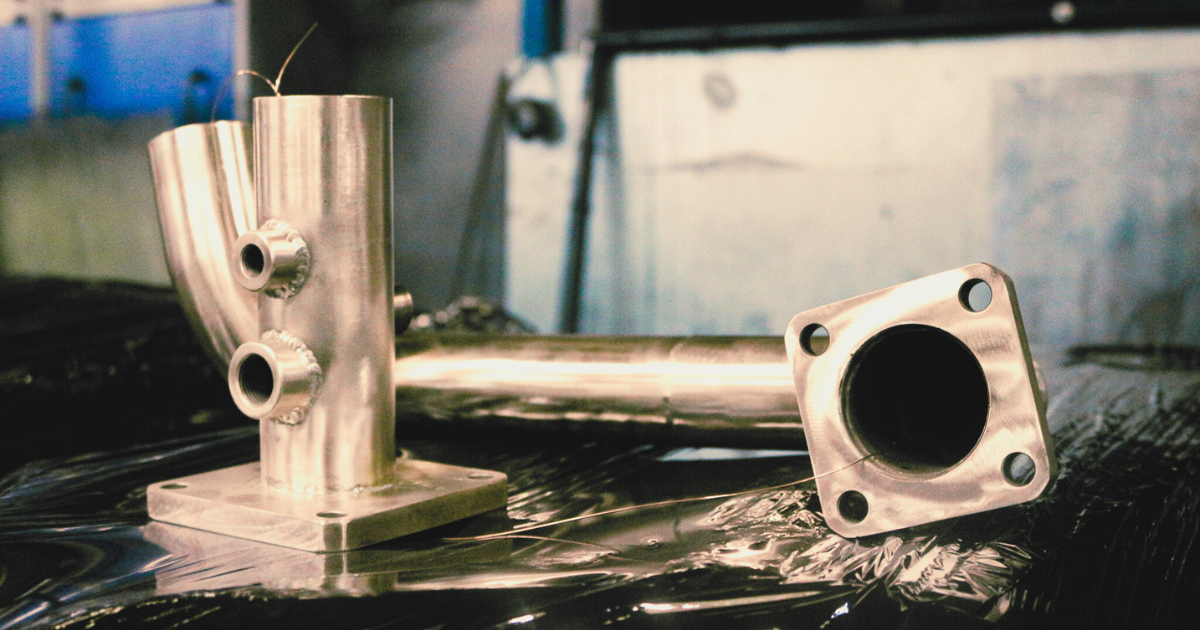

Expanding and Reducing

Furthermore, these complementary tube end forming processes alter tube diameter to enable telescopic connections or transitions between different pipe sizes. Expanding increases the end diameter whilst reducing decreases it, allowing for secure slip-fit assemblies.

Common Applications: Exhaust systems, ventilation ducting, structural assemblies

Swaging

Meanwhile, swaging creates smooth tapered transitions that improve fluid flow characteristics and simplify assembly procedures. This end forming method produces gradual diameter changes that reduce turbulence and pressure losses whilst facilitating easier insertion into mating components.

Common Applications: Fuel injection systems, precision instruments, aerospace components

Curling and Flanging

Subsequently, these techniques roll or reshape tube ends to eliminate sharp edges, increase structural strength, and provide mounting surfaces. Curling creates smooth, rounded edges for safety, whilst flanging produces flat surfaces for gasket sealing.

Common Applications: HVAC ducting, architectural elements, safety-critical components

Material Considerations and Capabilities

Therefore, end forming works with a wide range of materials, each presenting unique challenges and opportunities. Understanding material properties is crucial for successful tube end forming operations.

Stainless Steel

Consequently, stainless steel offers excellent formability with high strength retention. However, it requires proper lubrication and tooling to prevent galling. This makes it ideal for medical, food processing, and corrosive environments where quality standards are paramount.

Aluminium

Furthermore, aluminium provides lightweight characteristics with good formability, though it’s prone to work hardening. The end forming process requires careful temperature control and appropriate tooling materials to prevent pickup.

Carbon Steel

Meanwhile, carbon steel remains versatile and cost-effective, with predictable forming characteristics. It’s excellent for automotive and structural applications where corrosion resistance isn’t critical.

Brass and Copper

In addition, brass and copper offer excellent formability with superior corrosion resistance. These materials are commonly used in plumbing and HVAC applications where appearance and performance matter.

Frequently Asked Questions About End Forming

What is end forming used for?

End forming is used to create functional features on tube ends including flares for connections, beads for retention, expansions for slip-fits, and reductions for size transitions across automotive, aerospace, HVAC, and medical applications.

How does the end forming process work?

The end forming process uses specialised machinery to apply controlled mechanical force that reshapes tube ends without removing material, creating precise features through ram forming, segmented tooling, or rotary methods.

What materials work with end forming?

End forming works with various materials including stainless steel, aluminium, carbon steel, brass, and copper, each requiring specific tooling and process considerations for optimal results.

Conclusion

In conclusion, end forming has evolved from a simple tube modification process into a sophisticated manufacturing technique that enables complex assemblies, improves performance, and reduces costs across numerous industries. Understanding what end forming can achieve helps manufacturers optimise their tube fabrication processes.

Therefore, the tube end forming process offers unique advantages including material conservation, precision control, and versatile capabilities that make it indispensable in modern manufacturing. As technology continues advancing and new applications emerge, end forming will remain a critical capability for creating reliable, efficient tubular assemblies.

Subsequently, whether you’re designing automotive components, aerospace systems, or industrial equipment, understanding what end forming involves helps optimise designs for manufacturability whilst ensuring reliable performance in service. The key lies in matching the right forming method to your specific requirements, considering factors including volume, precision, materials, and economic constraints.

Finally, success in end forming comes from combining technical expertise with quality processes, appropriate equipment selection, and continuous improvement practices that deliver consistent results meeting the most demanding specifications. Understanding the end forming process thoroughly ensures optimal outcomes for any tube fabrication project.